my nozzle project

+2

John

SCOOBY

6 posters

Page 1 of 2

Page 1 of 2 • 1, 2

my nozzle project

my nozzle project

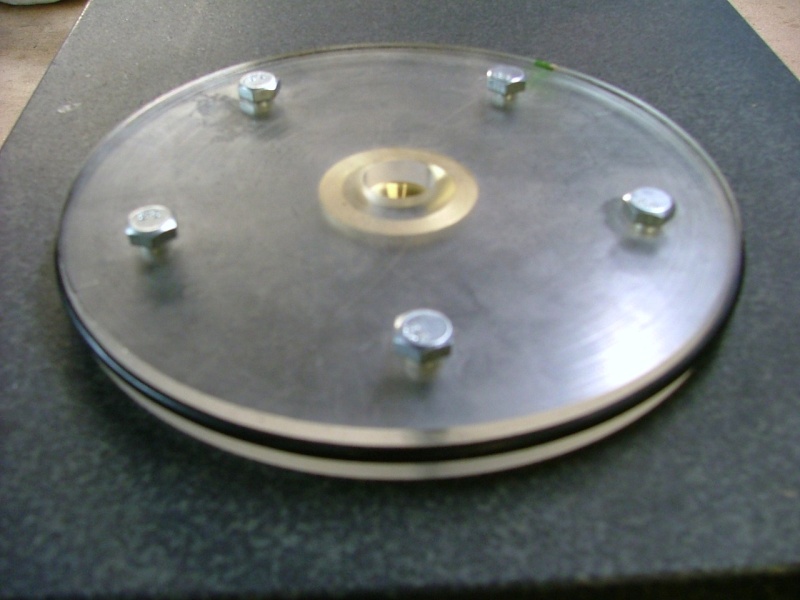

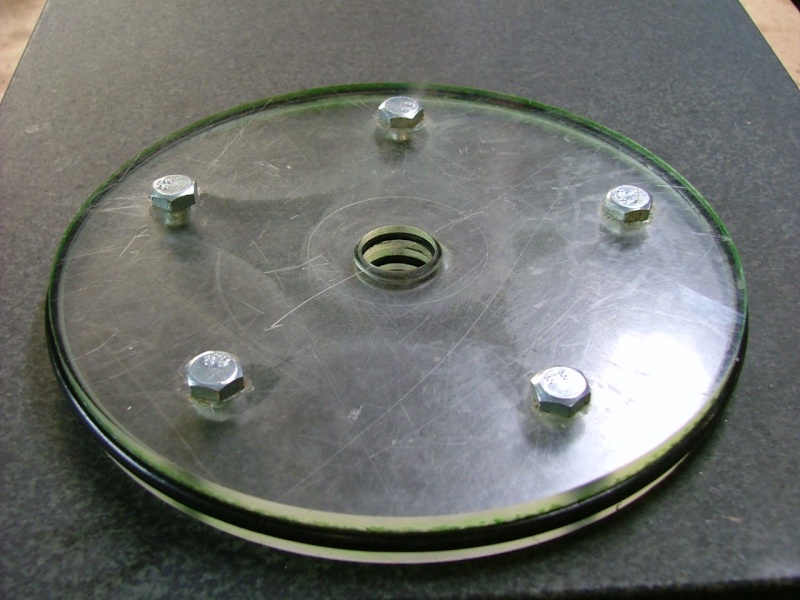

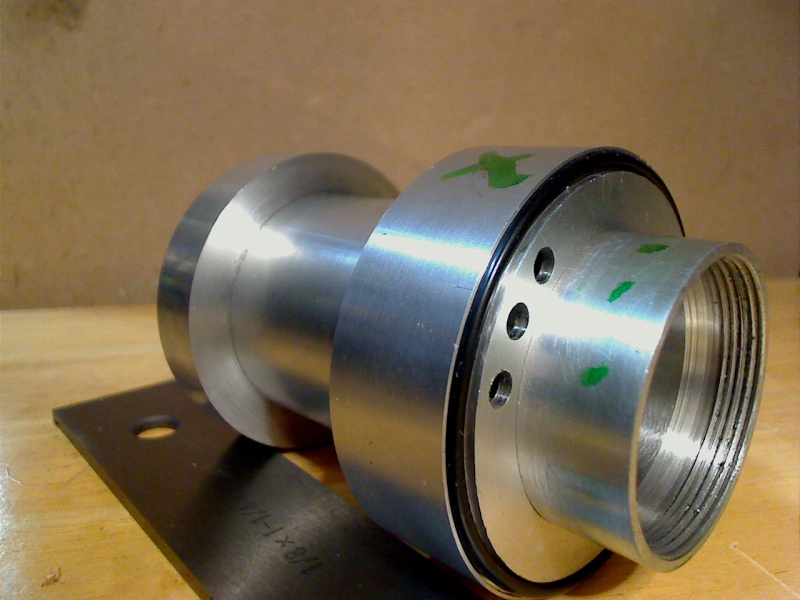

its only a 6" nozzle (its the biggest size pipe i had)

my camera decided to stop working, I'll post more once i figure out whats wrong with it

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

I love it! Great job on the top and bottom plate. That's my next goal is to update my nozzle to include on of those.

Re: my nozzle project

Re: my nozzle project

Fantastic top plate. How do we go about making a plate with a groove for the "o" ring like yours?

How much smaller must the diameter of the disc be relative to the inside diameter of the main tube?

How much "o" ring must stick out past the groove?

How much smaller must the diameter of the disc be relative to the inside diameter of the main tube?

How much "o" ring must stick out past the groove?

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Re: my nozzle project

Re: my nozzle project

This is how i went about constructing the plates:

-used a 6 in hole saw to cut the plates initially

-held the plates in a chuck and bored the inner hole for all of them to fit a fine threaded bolt and nut i had (.625 dia) (made it border line press fit)

-mounted all the plates on the bolt, used the nut to tighten them togeather, then held the end of the bold in a collet and turned the outside diameter of all the plates just till they were all round (i stacked 2 togeather for each plate, top and bottom, so they end up being about 1/2" thick each plate, top and bottom.

-i tend to go to the extreme with everything, being a perfectionist, so to get the bolt pattern perfect i had a old disc brake and centered that with the plates and drilled and tapped all of them so i could bolt the plates togeather

-as far as the outside oring groove, looked at what i had for o rings that i could use, they were a little small but streched ok, my chuck was about the same diameter as the turned plates, so i put the oring on that to see about how wide my groove should be, then ground a hss bit and turned away. Did alot of trial fitting because of course u can't add material back once u take it off.

I had about 3 ft of the 6in dia pipe, and i wanted to ensure the plates were perfectly perpendicular in the tube. I turned down 2 pieces of wood to fit the inside diameter exactly and on one left half of the piece of wood a larger diameter and center drilled the end (for tailstock support). This allowed me to hold the tube on the lathe (south bend heavy 10) without crushing the pipe in the chuck and it slipping out. After facing both ends, I made the spacer rings i needed by using a parting blade. I made 2 half inch wide rings to go on the ends of the pipe when assembled, so when i screwed those rings in flush with the top and bottom of the tube, and pushed the plates against them, it made sure both plates were perpendicular in the tube.

the copper pipe i had was about the same diamter of the holes i had made in the plates, so as before, i searched for orings that fit it, ground a cutter bit to bore out the groves, and did alot of trial fits. I opted for 2 inner o rings, this made it so the copper pipe was easier to keep straight in the tube and be perfectly centered. I dont have and lighting yet, but figured i'd eventually want to. The inner o rings make it so i can adjust the lighting distance to the exit orifice just by sliding the copper pipe in or out more. Another good thing about having that copper pipe in there is my first filter where the water comes in is smaller than the others. After looking at how zacharysc100 on youtube had his filter in the shape of a mushsroom kinda, i did the same thing, 'sept i'm using just smaller pads, and i made a hole in the middle of it so when mounted on the copper pipe they stayed centered, along with the other filters.

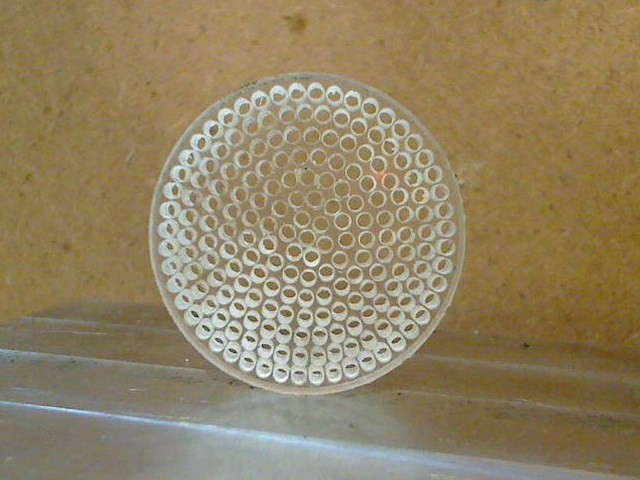

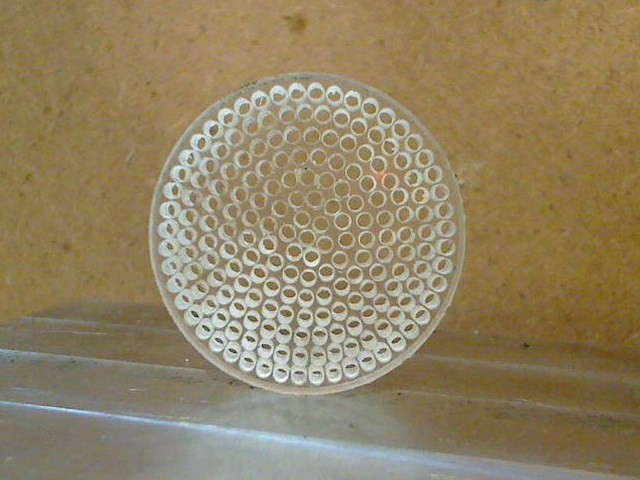

i didnt wanna have to pack straws again when and if i need to service the nozzle, so i found a piece of pvc that fit around the copper pipe and then proceded to pack straws in the flow straightener.

i'm still trying to see what type of filters work best and how many, space in between, etc.. so many variables to try. The space between my flow straightener and exit orfice is 1.250", that can be adjusted by just making more spacer rings of different width.

hopefully i'll be able to take more pics soon

-used a 6 in hole saw to cut the plates initially

-held the plates in a chuck and bored the inner hole for all of them to fit a fine threaded bolt and nut i had (.625 dia) (made it border line press fit)

-mounted all the plates on the bolt, used the nut to tighten them togeather, then held the end of the bold in a collet and turned the outside diameter of all the plates just till they were all round (i stacked 2 togeather for each plate, top and bottom, so they end up being about 1/2" thick each plate, top and bottom.

-i tend to go to the extreme with everything, being a perfectionist, so to get the bolt pattern perfect i had a old disc brake and centered that with the plates and drilled and tapped all of them so i could bolt the plates togeather

-as far as the outside oring groove, looked at what i had for o rings that i could use, they were a little small but streched ok, my chuck was about the same diameter as the turned plates, so i put the oring on that to see about how wide my groove should be, then ground a hss bit and turned away. Did alot of trial fitting because of course u can't add material back once u take it off.

I had about 3 ft of the 6in dia pipe, and i wanted to ensure the plates were perfectly perpendicular in the tube. I turned down 2 pieces of wood to fit the inside diameter exactly and on one left half of the piece of wood a larger diameter and center drilled the end (for tailstock support). This allowed me to hold the tube on the lathe (south bend heavy 10) without crushing the pipe in the chuck and it slipping out. After facing both ends, I made the spacer rings i needed by using a parting blade. I made 2 half inch wide rings to go on the ends of the pipe when assembled, so when i screwed those rings in flush with the top and bottom of the tube, and pushed the plates against them, it made sure both plates were perpendicular in the tube.

the copper pipe i had was about the same diamter of the holes i had made in the plates, so as before, i searched for orings that fit it, ground a cutter bit to bore out the groves, and did alot of trial fits. I opted for 2 inner o rings, this made it so the copper pipe was easier to keep straight in the tube and be perfectly centered. I dont have and lighting yet, but figured i'd eventually want to. The inner o rings make it so i can adjust the lighting distance to the exit orifice just by sliding the copper pipe in or out more. Another good thing about having that copper pipe in there is my first filter where the water comes in is smaller than the others. After looking at how zacharysc100 on youtube had his filter in the shape of a mushsroom kinda, i did the same thing, 'sept i'm using just smaller pads, and i made a hole in the middle of it so when mounted on the copper pipe they stayed centered, along with the other filters.

i didnt wanna have to pack straws again when and if i need to service the nozzle, so i found a piece of pvc that fit around the copper pipe and then proceded to pack straws in the flow straightener.

i'm still trying to see what type of filters work best and how many, space in between, etc.. so many variables to try. The space between my flow straightener and exit orfice is 1.250", that can be adjusted by just making more spacer rings of different width.

hopefully i'll be able to take more pics soon

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

Thanks for such a detailed report - very helpful - now I have to figure out how to do a work around for not having a lathe.

Another question - I noticed that your water inlet is perfect - how did you cut your hole to fit the water inlet pipe?

It seems when drilling a hole - at an angle - into a curved surface( of the main tube) the drilled hole comes out oblong.

Any helpful hints.

Another question - I noticed that your water inlet is perfect - how did you cut your hole to fit the water inlet pipe?

It seems when drilling a hole - at an angle - into a curved surface( of the main tube) the drilled hole comes out oblong.

Any helpful hints.

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Re: my nozzle project

Re: my nozzle project

for the input pipe, first i put in the bottom plate and ring, and put in the long bolt i used with the collet and nut and held the bolt in the vise. (i have an X2 mini mill) I dial indicated the tube to make sure it was square. then i used the dial indicator to center the spindle over the tube. Since i know the tubes inside diameter and the inlet pipe's that i was going to uses outside diameter i just did the math to figure out how far off center i needed to go to make it perfectly tangent.

divide inside pipe dia by 2, and after centering spindle over tube, move that amount over, that'll put the spindle centered on the edge of the tube. Measure the outside diameter of your input pipe and divide that by 2 and move back that amount. For the hole i used a milling bit, but biggest i have is half inch, so after i used a router bit i had (one without a bearing) and that opened it up to enough where i can use the same boring bar thing i used to make the inner o ring grooves. To get the cutter bit in the bar opened to the right amount, i held a piece of the inlet tube in the chuck and in the tailstock drillchuck, held the boring bar. I just then adjust the cutter bit so it would cut the exact diameter i wanted. I initually cut the end of the inlet pipe to knotch it to match with the 6" hole saw, but it wasnt an exact arc match so after boring the hole and putting the pipe in, i dremel'd it to match

divide inside pipe dia by 2, and after centering spindle over tube, move that amount over, that'll put the spindle centered on the edge of the tube. Measure the outside diameter of your input pipe and divide that by 2 and move back that amount. For the hole i used a milling bit, but biggest i have is half inch, so after i used a router bit i had (one without a bearing) and that opened it up to enough where i can use the same boring bar thing i used to make the inner o ring grooves. To get the cutter bit in the bar opened to the right amount, i held a piece of the inlet tube in the chuck and in the tailstock drillchuck, held the boring bar. I just then adjust the cutter bit so it would cut the exact diameter i wanted. I initually cut the end of the inlet pipe to knotch it to match with the 6" hole saw, but it wasnt an exact arc match so after boring the hole and putting the pipe in, i dremel'd it to match

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

You can check out some of my early work here - https://laminar.forumotion.com/laminar-nozzle-talk-and-pictures-f1/my-project-t72-30.htm - but I need to improve my design.

Do you think I could take a rough cut diameter circle of pvc and somehow use a dremel to cut the final finished diameter and an o-ring groove?

Do you think I could take a rough cut diameter circle of pvc and somehow use a dremel to cut the final finished diameter and an o-ring groove?

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Re: my nozzle project

Re: my nozzle project

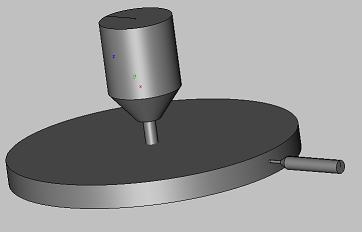

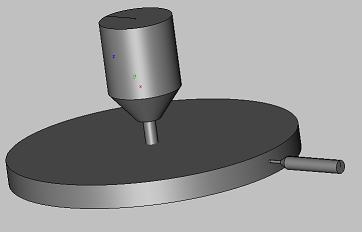

got a drill press to hold it in? or maybe a drill u can keep locked on and held in a vise, u could just use ur dremel like this to cut the o ring

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

Google sketch up that quick? Cool.

That will work for me. You also gave me other ways to accomplish the same thing with the tools I have. Thanks

That will work for me. You also gave me other ways to accomplish the same thing with the tools I have. Thanks

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Re: my nozzle project

Re: my nozzle project

nah i have viacad 3d pro, i got solidworks and other cad software, but i'm kinda self teaching myself on all of them, viacad i'm fastest at

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

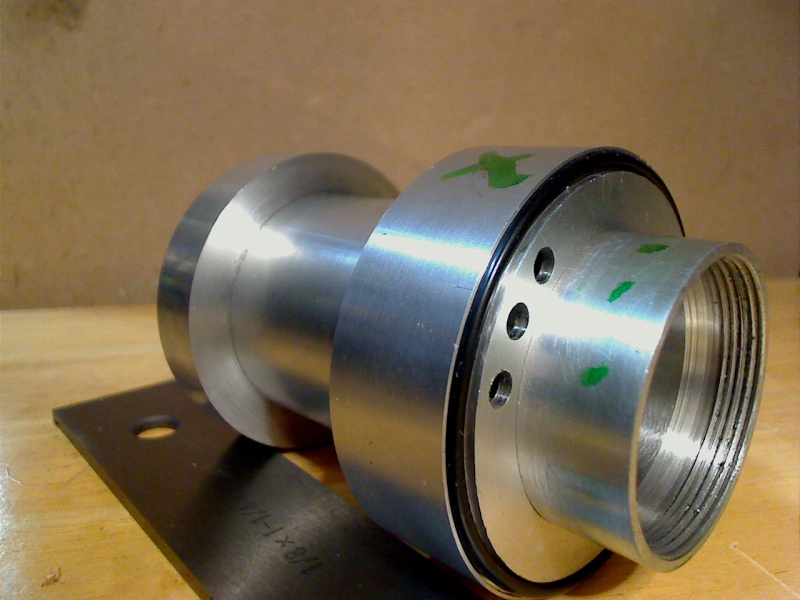

So round 2, got my camera going and started on a mini nozzle.

Theres will be 2 chambers, inlet will be at the green x (not sure if i should have it tangental or not) and go through a ring (more than 3 holes of course, not finished) then through holes drilled around primary chamber (green dots)

Theres will be 2 chambers, inlet will be at the green x (not sure if i should have it tangental or not) and go through a ring (more than 3 holes of course, not finished) then through holes drilled around primary chamber (green dots) the top of course needs to be turned down and the orifice cut

the top of course needs to be turned down and the orifice cut  these holes are .108 thou diameter. Thanks to cnc, this whole thing took only about 10 min to make while i watched tv.

these holes are .108 thou diameter. Thanks to cnc, this whole thing took only about 10 min to make while i watched tv.

The next one i should make with smaller holes i assume. Any recomendations to the design would be appreciated

Theres will be 2 chambers, inlet will be at the green x (not sure if i should have it tangental or not) and go through a ring (more than 3 holes of course, not finished) then through holes drilled around primary chamber (green dots)

Theres will be 2 chambers, inlet will be at the green x (not sure if i should have it tangental or not) and go through a ring (more than 3 holes of course, not finished) then through holes drilled around primary chamber (green dots) the top of course needs to be turned down and the orifice cut

the top of course needs to be turned down and the orifice cut  these holes are .108 thou diameter. Thanks to cnc, this whole thing took only about 10 min to make while i watched tv.

these holes are .108 thou diameter. Thanks to cnc, this whole thing took only about 10 min to make while i watched tv.

The next one i should make with smaller holes i assume. Any recomendations to the design would be appreciated

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

I can't say anything right now because I am drooling too much!!!!

That looks great! I like the inlet chamber, and my GUESS would be that tangential is not going to matter.

What material did you make it out of? Do you own a lathe?

That looks great! I like the inlet chamber, and my GUESS would be that tangential is not going to matter.

What material did you make it out of? Do you own a lathe?

Re: my nozzle project

Re: my nozzle project

i have a south bend heavy 10 and x2 mini mill which i converted to cnc and also extended the x and y axis on it. Material is aluminum

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

so i'm about to drill the holes that go into the main chamber and was wondering if my thinking was correct.

Say for instance my first ring has 20 holes .187 inches in diameter. Should i calculate the total area of all holes combined and make # of holes and size (find total area) that i drill into the main chamber equal to it? And same for the plates inside with holes. As the holes get smaller, i make more holes, but would making the area equal be a good idea?

I tend to think too much about things.. brain hurts.. haha

Say for instance my first ring has 20 holes .187 inches in diameter. Should i calculate the total area of all holes combined and make # of holes and size (find total area) that i drill into the main chamber equal to it? And same for the plates inside with holes. As the holes get smaller, i make more holes, but would making the area equal be a good idea?

I tend to think too much about things.. brain hurts.. haha

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

By applying fluidmechanical equiations you can prove that you will always get a pressuredrop when going through each stage of orifices (holes). I'll not bore you with the details but the result is this: Smaller area of orifice = higher drop of pressure through holes.

To minimize the drop in pressure you will want to maximize the total area for water to flow. So progress to smaller holes but have lots of them to avoid large drops in pressure.

EDIT: Both nozzles look awesome by the way! Thumbs up! I plan to do some of the same things as you - CNC the end plates and use a lathe to make a groove for an O-ring, and we'll see how the outcome is.

I plan to do some of the same things as you - CNC the end plates and use a lathe to make a groove for an O-ring, and we'll see how the outcome is.

To minimize the drop in pressure you will want to maximize the total area for water to flow. So progress to smaller holes but have lots of them to avoid large drops in pressure.

EDIT: Both nozzles look awesome by the way! Thumbs up!

Steffen- Nozzle Newbie

- Posts : 11

Join date : 2010-01-15

Re: my nozzle project

Re: my nozzle project

so in the first chamber the ring has 20 holes, .185 inches diameter.

total area is pie r squared which is (.185/2) = .0925 squared x pie = .026866625 x 20 holes = .5373325 area

I don't have a rotary table or indexer but the gear on the back of the lathe has 40 teeth. So i held a scribe in the toolpost and marked 40 lines off. To figure out the size of the drill bit i just worked backwards.

(.5373325/40)/Pie = .004278125 squarooterized = .065407377, which is the radius so x2 = .131 rounded. So i drilled 40 holes that size.. working on the orifice now

total area is pie r squared which is (.185/2) = .0925 squared x pie = .026866625 x 20 holes = .5373325 area

I don't have a rotary table or indexer but the gear on the back of the lathe has 40 teeth. So i held a scribe in the toolpost and marked 40 lines off. To figure out the size of the drill bit i just worked backwards.

(.5373325/40)/Pie = .004278125 squarooterized = .065407377, which is the radius so x2 = .131 rounded. So i drilled 40 holes that size.. working on the orifice now

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

Same numbers as I got. Looking foreward to seeing the result!

Steffen- Nozzle Newbie

- Posts : 11

Join date : 2010-01-15

Re: my nozzle project

Re: my nozzle project

got another one done. The holes are .078 inches in diameter. And yes, i think i'm gonna go smaller

SCOOBY- Nozzle Newbie

- Posts : 17

Join date : 2010-05-10

Re: my nozzle project

Re: my nozzle project

Fantastic work - I feel silly asking such a simple question again after seeing your advanced work.

I looked at your description for finding the tangential water inlet location - for drilling the hole - and want to give a made up example to clarify things.

Say the inside diameter of the tube is 8.0 inches and the outside diameter is 8.5 inches (again made up numbers).

What is the math to determine drilling location. Will that be the center for the drilling?

It also seems when drilling a circle into the outside curve of the tube the drilled hole comes out oblong? If so, how do I correct it to fit a round water inlet tube?

Thanks.

I looked at your description for finding the tangential water inlet location - for drilling the hole - and want to give a made up example to clarify things.

Say the inside diameter of the tube is 8.0 inches and the outside diameter is 8.5 inches (again made up numbers).

What is the math to determine drilling location. Will that be the center for the drilling?

It also seems when drilling a circle into the outside curve of the tube the drilled hole comes out oblong? If so, how do I correct it to fit a round water inlet tube?

Thanks.

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Re: my nozzle project

Re: my nozzle project

I made an illustration to show how you find the distance to the center of inlet covewi. This shows the nozzle tube from the side.

As the illustration shows:

x1 is the distance from the centerline of the nozzle tube to the center of inlet

x2 is the distance from the outer edge of the nozzle tube to the center of inlet

So in your example, and with a 1 inch inlet hole you get:

x1 = (8-1)/2 = 3,5 inches from the centerline

or

x2 = (8.5-8+1)/2 = 0.75 inches from the edge of tube

If you add these two numbers up you get 3.5 + 0.75 = 4.25 and that is the radius of the tube (8.5/2 = 4.25) so the math is correct.

Just change OD,ID and d in the equations in the illustration with your numbers and you will get the correct distances for a hole that is perfectly tangent to the inner edge of a tube.

As the illustration shows:

x1 is the distance from the centerline of the nozzle tube to the center of inlet

x2 is the distance from the outer edge of the nozzle tube to the center of inlet

So in your example, and with a 1 inch inlet hole you get:

x1 = (8-1)/2 = 3,5 inches from the centerline

or

x2 = (8.5-8+1)/2 = 0.75 inches from the edge of tube

If you add these two numbers up you get 3.5 + 0.75 = 4.25 and that is the radius of the tube (8.5/2 = 4.25) so the math is correct.

Just change OD,ID and d in the equations in the illustration with your numbers and you will get the correct distances for a hole that is perfectly tangent to the inner edge of a tube.

Last edited by Steffen on Sat May 22, 2010 5:51 am; edited 1 time in total

Steffen- Nozzle Newbie

- Posts : 11

Join date : 2010-01-15

Re: my nozzle project

Re: my nozzle project

Steffen Thanks

The illustration would be helpful - did not seem to show up on your posting.

The illustration would be helpful - did not seem to show up on your posting.

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Re: my nozzle project

Re: my nozzle project

Wierd! Shows up on mine. Will try to upload it to another host asap.

Steffen- Nozzle Newbie

- Posts : 11

Join date : 2010-01-15

Re: my nozzle project

Re: my nozzle project

Math is a beautiful thing - thanks.

Who said in grammer school - " I will never use this stuff"

Who said in grammer school - " I will never use this stuff"

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Ike's Prototype Project - My first laminar nozzle

» Khattak's Laminar Flow Nozzle Project

» Liteglow`s laminar project

» My Project

» NEW PROJECT TIME

» Khattak's Laminar Flow Nozzle Project

» Liteglow`s laminar project

» My Project

» NEW PROJECT TIME

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum