Aluminum Outlet - exit hole for laminar flow nozzle

2 posters

Page 1 of 1

Aluminum Outlet - exit hole for laminar flow nozzle

Aluminum Outlet - exit hole for laminar flow nozzle

Hello all,

This is my first post here. I've become obsessed with making a laminar flow fountain in the last few days. I've read a lot, watch many videos, and now I'm making my own. After at least 5 trips to home depost, my first couple attempts are not too bad, but I know I can do better. The flow is still wobbling a bit, and the stream is not perfect. I'm making little changes here and there to try to improve it. My goal is to end up with the biggest, longest, and cleanest stream possible from a 4" PVC pipe.

I have many many questions, but I'll start first with the exit hole, because this seems to be one of the most important pieces of the puzzle.

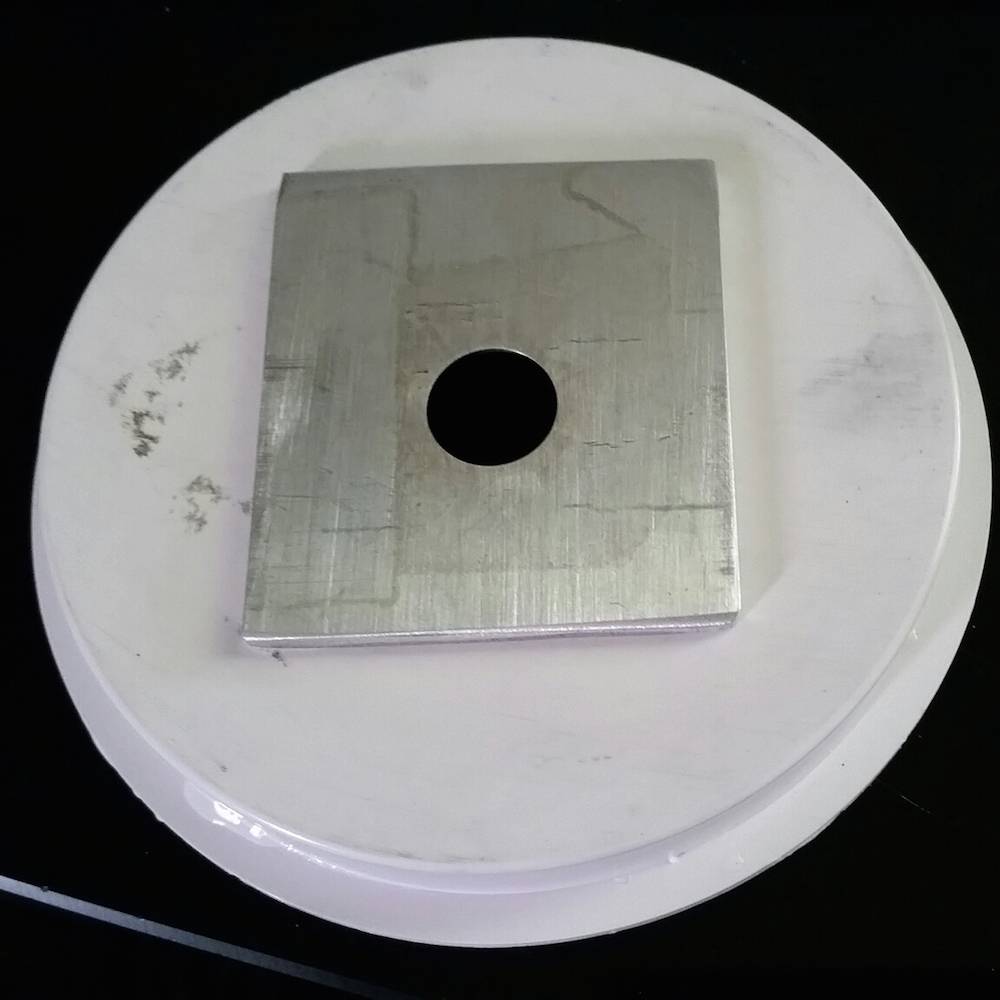

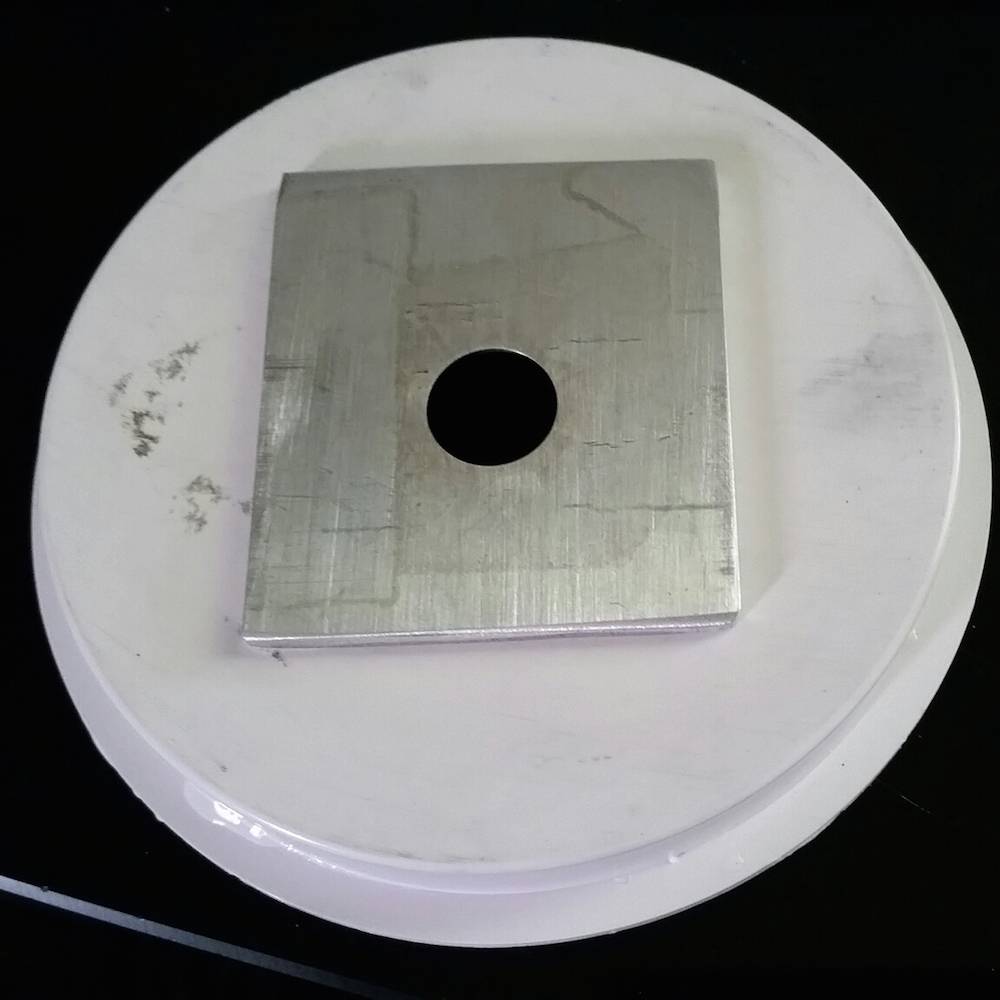

I'm using 1/8" aluminum and a countersink tool to cut the hole to about 1/2":

Then I use 400 grit sandpaper to smooth out the edges of the hole:

Then I siliconed it to the inside of the "knock out" cap:

Here is a picture of the water stream:

Here are my questions about the exit hole:

1. I THINK the hole is pretty clean. Does it look clean enough? Is there anything wrong with my process?

2. Is it ok to silicone the square on to the back side of the knock out cap? Or does the back side need to be perfectly flat?

3. I read on a youtube video somewhere that there is someone on this board who makes these exit holes. Can someone point me to him? Maybe I should just buy one?

Here is a video of it running.

This is my first post here. I've become obsessed with making a laminar flow fountain in the last few days. I've read a lot, watch many videos, and now I'm making my own. After at least 5 trips to home depost, my first couple attempts are not too bad, but I know I can do better. The flow is still wobbling a bit, and the stream is not perfect. I'm making little changes here and there to try to improve it. My goal is to end up with the biggest, longest, and cleanest stream possible from a 4" PVC pipe.

I have many many questions, but I'll start first with the exit hole, because this seems to be one of the most important pieces of the puzzle.

I'm using 1/8" aluminum and a countersink tool to cut the hole to about 1/2":

Then I use 400 grit sandpaper to smooth out the edges of the hole:

Then I siliconed it to the inside of the "knock out" cap:

Here is a picture of the water stream:

Here are my questions about the exit hole:

1. I THINK the hole is pretty clean. Does it look clean enough? Is there anything wrong with my process?

2. Is it ok to silicone the square on to the back side of the knock out cap? Or does the back side need to be perfectly flat?

3. I read on a youtube video somewhere that there is someone on this board who makes these exit holes. Can someone point me to him? Maybe I should just buy one?

Here is a video of it running.

guytimes- Nozzle Newbie

- Posts : 4

Join date : 2015-06-25

Re: Aluminum Outlet - exit hole for laminar flow nozzle

Re: Aluminum Outlet - exit hole for laminar flow nozzle

Welcome to the forums!

As for the nozzle, that looks like a really nicely done exit point. I am a little concerned about the gluing to the back of the end cap though. You want the final chamber to be as smooth as possible and the outside edge of the metal makes a lip that can deflect the water to disturb the laminar fountain.

When I built my first fountain I cut a hole in the top plate to match the size of the round metal nozzle piece and then used lock-tite epoxy to secure it in place. A round aluminum blank is a great thing to cut in to a nozzle as you can usually find them in standard size that match the size of a fostner bit or hole saw. Then they just glue in place in the top plate. You want the bottom of the nozzle flush with the bottom of the top plate so you have a completely flat surface. Keep up the good work and keep posting your progress and questions here!

As for the nozzle, that looks like a really nicely done exit point. I am a little concerned about the gluing to the back of the end cap though. You want the final chamber to be as smooth as possible and the outside edge of the metal makes a lip that can deflect the water to disturb the laminar fountain.

When I built my first fountain I cut a hole in the top plate to match the size of the round metal nozzle piece and then used lock-tite epoxy to secure it in place. A round aluminum blank is a great thing to cut in to a nozzle as you can usually find them in standard size that match the size of a fostner bit or hole saw. Then they just glue in place in the top plate. You want the bottom of the nozzle flush with the bottom of the top plate so you have a completely flat surface. Keep up the good work and keep posting your progress and questions here!

Ike- Nozzle Novice

- Posts : 74

Join date : 2010-05-03

Age : 40

Location : Wyoming

Re: Aluminum Outlet - exit hole for laminar flow nozzle

Re: Aluminum Outlet - exit hole for laminar flow nozzle

PS Your stream looks really good! Your build also looks really nice and clean!

If you added a small low pass filter (air damper chamber) between the fountain and pump it might help with some of that last little bit of fluctuation in flow.

If you added a small low pass filter (air damper chamber) between the fountain and pump it might help with some of that last little bit of fluctuation in flow.

Ike- Nozzle Novice

- Posts : 74

Join date : 2010-05-03

Age : 40

Location : Wyoming

Re: Aluminum Outlet - exit hole for laminar flow nozzle

Re: Aluminum Outlet - exit hole for laminar flow nozzle

Thanks for the advice, Ike. I've ordered a bit 1/8" piece of aluminum for my exit hole and I'll use it for the entire top so it will be perfectly flat. I'll keep you guys posted and let you know if it helps the flow. I've also started on a 24" x 4" low pass filter.

For the exit hole, I've noticed that just the finest blemish will ruin the flow. To make the hole, I drill a 3/8" hole and then I'm using a countersink tool to open it up and put the angle on. But the countersink tool doesn't cut the greatest. It is really difficult to prevent it from chattering, the aluminum gets hot, etc. I use a magnifying glass to inspect the hole and then smooth it out with sandpaper.

I've made about 5 exit holes, and for whatever reason, 2 of them work better (on the same fountain) than all the others, even though they all look great under the scope. I've found many people showing off their nozzle, but none of them really show close up pictures of the exit hole.

Question, when the fountain is running, what can I look for in the stream to know if my exit hole needs to be refined or not? The slower the flow, the more clear the water is where it exits the hole. Should I be looking for the water to be as clear as possible right where it comes out, at high flow? Sometimes I look at the stream and I can see tiny lines on the perimeter of the water stream.

For the exit hole, I've noticed that just the finest blemish will ruin the flow. To make the hole, I drill a 3/8" hole and then I'm using a countersink tool to open it up and put the angle on. But the countersink tool doesn't cut the greatest. It is really difficult to prevent it from chattering, the aluminum gets hot, etc. I use a magnifying glass to inspect the hole and then smooth it out with sandpaper.

I've made about 5 exit holes, and for whatever reason, 2 of them work better (on the same fountain) than all the others, even though they all look great under the scope. I've found many people showing off their nozzle, but none of them really show close up pictures of the exit hole.

Question, when the fountain is running, what can I look for in the stream to know if my exit hole needs to be refined or not? The slower the flow, the more clear the water is where it exits the hole. Should I be looking for the water to be as clear as possible right where it comes out, at high flow? Sometimes I look at the stream and I can see tiny lines on the perimeter of the water stream.

guytimes- Nozzle Newbie

- Posts : 4

Join date : 2015-06-25

Similar topics

Similar topics» My first try at a laminar flow nozzle

» This is my first Laminar Water Flow Nozzle.

» Khattak's Laminar Flow Nozzle Project

» Tips on Exit Nozzle

» The CD nozzle outlet

» This is my first Laminar Water Flow Nozzle.

» Khattak's Laminar Flow Nozzle Project

» Tips on Exit Nozzle

» The CD nozzle outlet

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum