Video of latest test of the Mk2

+3

JohnJarvis

liteglow

oldsparky

7 posters

Page 1 of 1

Video of latest test of the Mk2

Video of latest test of the Mk2

Well ..... since I have to work outside (I have that sort of workshop that is now mostly a storage shed  ) I took advantage of the start of the decent weather to build a frame, so that I could set and hold the 8" nozzle in position.

) I took advantage of the start of the decent weather to build a frame, so that I could set and hold the 8" nozzle in position.

Enjoy.

There are three movies to be seen ...... I could only ever get one to present itself here

Watch all three on the YouTube site I guess.

Bye for now.

Don't get too wet.

Oldsparky.

Enjoy.

There are three movies to be seen ...... I could only ever get one to present itself here

Watch all three on the YouTube site I guess.

Bye for now.

Don't get too wet.

Oldsparky.

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

That is awesome !! great job.

Dont be disappointed with that laminar.

You have a extremely high and long arc of water..

I bet if you reduce the pump some bit, the water will stay laminar ALL way until its end.

The reason why the water break up in the end can also be some small wind .

Just a tiny bit of wind can break up the water flow.

Small bubbles in the nozzle can also create turbulence.

But I guess the pump pressure is to high compared to the diameter of the nozzle.

Dont be disappointed with that laminar.

You have a extremely high and long arc of water..

I bet if you reduce the pump some bit, the water will stay laminar ALL way until its end.

The reason why the water break up in the end can also be some small wind .

Just a tiny bit of wind can break up the water flow.

Small bubbles in the nozzle can also create turbulence.

But I guess the pump pressure is to high compared to the diameter of the nozzle.

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

Thanks for your response liteglow ...... I did top up the water level later and the arc increased ..... I had to adjust the nozzle angle to still hit the target

I'm happy now with the final quality of the laminar flow from the nozzle but its still a work in progress ...... they always are aren't they ?

Bye for now.

Don't get too wet.

Oldsparky.

I'm happy now with the final quality of the laminar flow from the nozzle but its still a work in progress ...... they always are aren't they ?

Bye for now.

Don't get too wet.

Oldsparky.

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

Excellent result. As a matter of interest where did you get your tube from?(In the UK midlands) I am still struggling with a smooth bore but corrugated outer, whicn makes collar making difficult.

JohnJarvis- Nozzle Newbie

- Posts : 24

Join date : 2009-04-17

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

this looks great mate i am after that sort of height and length i want my laminar jet to jump over a bridge that i have going over my pond so that i can walk under it i have a few questions if you could answer them for me what size tubing are you using can you please give more info i.e. diamiter and length

what are you using for the brass nozzle it looks like some sort of back plate for a door knob

what size pump are you using i.e. ltr per hour

hope you can help

thanks colin

what are you using for the brass nozzle it looks like some sort of back plate for a door knob

what size pump are you using i.e. ltr per hour

hope you can help

thanks colin

colinley- Nozzle Newbie

- Posts : 12

Join date : 2010-03-31

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

Hi there John / Colin.

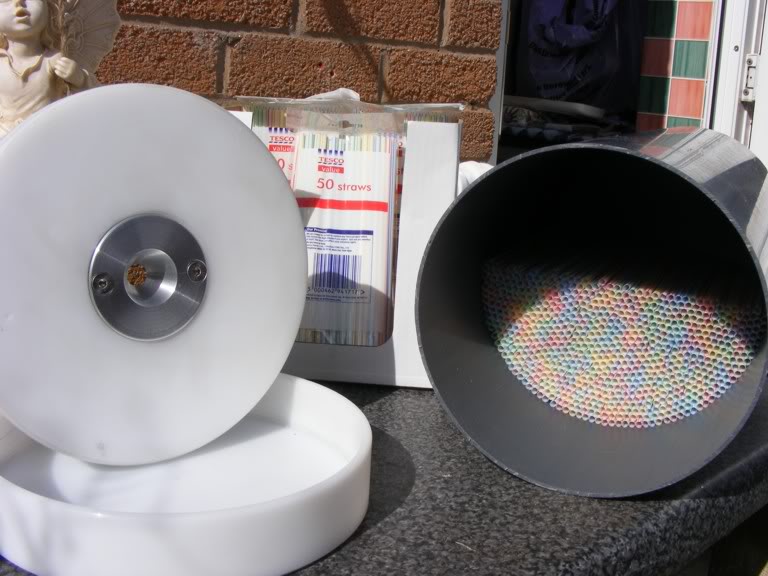

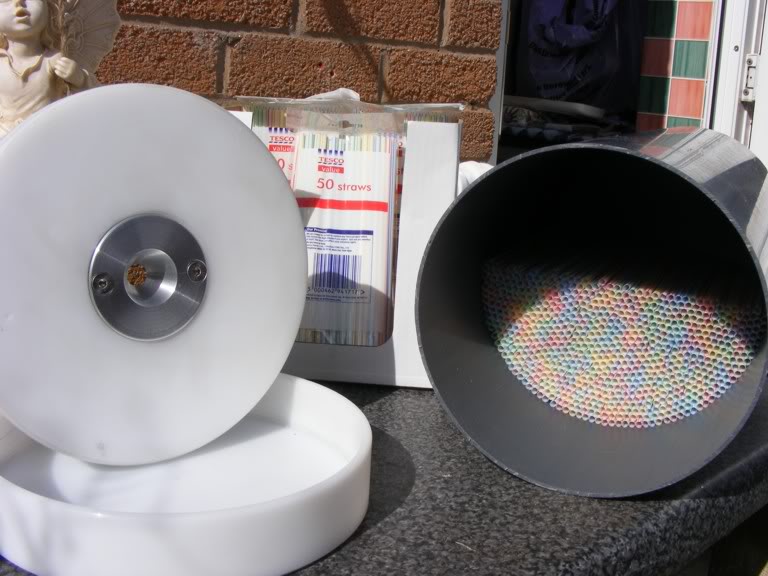

The Laminar nozzle propper, is turned from aluminium and set into a p.t.f.e. turned endcap.

The nozzle endcap and seal endcap are an interference fit (still sealed with silicon and fixed with self-tappers), fitted to an 8" waste pipe.

I errrr aquired the pipe from a friendly industrial work colleague

I errrr aquired the pipe from a friendly industrial work colleague

Filled with drinking straws.

It has a tangential pipe for water flow inlet .... and my wife's frying pan splatter guard for a mesh to hold the straws in place.

The pump is WIEPRO 7,800 Ltr/hr delivery.

I made a low-pass filter from 4" waste pipe sealed either end.

I hope this helps ... I'll be more specific with dimentions if you need.

Bye for now.

Don't get too wet.

Oldsparky

The brass is just for show I'm afraidwhat are you using for the brass nozzle it looks like some sort of back plate for a door knob

The Laminar nozzle propper, is turned from aluminium and set into a p.t.f.e. turned endcap.

The nozzle endcap and seal endcap are an interference fit (still sealed with silicon and fixed with self-tappers), fitted to an 8" waste pipe.

John .... I'm going to have to claim the 5th Ammendment on this oneAs a matter of interest where did you get your tube from?(In the UK midlands)

Filled with drinking straws.

It has a tangential pipe for water flow inlet .... and my wife's frying pan splatter guard for a mesh to hold the straws in place.

The pump is WIEPRO 7,800 Ltr/hr delivery.

I made a low-pass filter from 4" waste pipe sealed either end.

I hope this helps ... I'll be more specific with dimentions if you need.

Bye for now.

Don't get too wet.

Oldsparky

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

That is fantastic work!

congratulations! Do you have the lights set up already? show us more videos!

I'm inspired by you!

congratulations! Do you have the lights set up already? show us more videos!

I'm inspired by you!

Lindenmeyer- Nozzle Newbie

- Posts : 16

Join date : 2009-04-29

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

Thank you for your kind words Eduardo.

I haven't started on the electronics of lighting the laminar stream yet, but I've made provision for fibre-optic cable entry into the nozzle by mounting a plastic tube (15mm O.D. 12mm I.D.) down the center of the nozzle.

I have 3mm sheathed fibre-optic cable ready ... I now need to start thinking about getting L.E.D's (maybe 5W).

Then there's a power supply ..... heat sinks ... current limit resistors .... waterproof enclosure ... ohhhhhh lots 'n' lots to do yet

Bye bye for now.

Don't get too wet.

Oldsparky.

I haven't started on the electronics of lighting the laminar stream yet, but I've made provision for fibre-optic cable entry into the nozzle by mounting a plastic tube (15mm O.D. 12mm I.D.) down the center of the nozzle.

I have 3mm sheathed fibre-optic cable ready ... I now need to start thinking about getting L.E.D's (maybe 5W).

Then there's a power supply ..... heat sinks ... current limit resistors .... waterproof enclosure ... ohhhhhh lots 'n' lots to do yet

Bye bye for now.

Don't get too wet.

Oldsparky.

laminar diameter

laminar diameter

hey your laminar is perfectly clear - but we're about doin' it even better ... stop joking

everyone of our trial to get the best nozzle failed. so can u tell us how to build the perfect nozzle - and if it's your holy secret, won't u tell us something about the diameter of your supertrooper fibre-obtic laminar?

desperatly seeking the perfect nozzle

andreas

everyone of our trial to get the best nozzle failed. so can u tell us how to build the perfect nozzle - and if it's your holy secret, won't u tell us something about the diameter of your supertrooper fibre-obtic laminar?

desperatly seeking the perfect nozzle

andreas

maddengel- Nozzle Newbie

- Posts : 1

Join date : 2010-04-21

Age : 42

Location : Germany

Re: Video of latest test of the Mk2

Re: Video of latest test of the Mk2

Hello Andreas.

errrrrrrr ............... No

I'm a bit of a Nozzle Newbie myself you see ... I've learned what little I know from the more experienced members of this forum like Liteglow, John and Magic-Nozzle.

Check out Liteglow's description of building a basic laminar nozzle.

The Guide To Laminar Flow

All at this forum owe our chance to play laminar fountains to the inventor/designer of the concept, a gentleman called Mark Fuller

My advice would be to spend some time first, reading and taking on-board the experiences and idea's of some the great guys here at the forum.

Bye for now.

Good luck.

And don't get too wet.

Oldsparky.

so can u tell us how to build the perfect nozzle

errrrrrrr ............... No

I'm a bit of a Nozzle Newbie myself you see ... I've learned what little I know from the more experienced members of this forum like Liteglow, John and Magic-Nozzle.

Check out Liteglow's description of building a basic laminar nozzle.

The Guide To Laminar Flow

All at this forum owe our chance to play laminar fountains to the inventor/designer of the concept, a gentleman called Mark Fuller

My advice would be to spend some time first, reading and taking on-board the experiences and idea's of some the great guys here at the forum.

Bye for now.

Good luck.

And don't get too wet.

Oldsparky.

Great Work

Great Work

I did a set up like yours - check out the photos at the bottom of this page - https://laminar.forumotion.com/laminar-nozzle-talk-and-pictures-f1/my-project-t72-45.htm

I had a horrible water leak around the the fibers as they came out of the pvc tube. What are your thoughts to prevent water leaks yet still support for the fibers?

I had a horrible water leak around the the fibers as they came out of the pvc tube. What are your thoughts to prevent water leaks yet still support for the fibers?

covewi- Nozzle Pro

- Posts : 248

Join date : 2009-06-07

Similar topics

Similar topics» Pentair Flow jet

» Liteglow`s twin Laminar Jumping Jets :)

» Magic_Nozzle's Laminar Project

» My project build thread...

» My Laminar Garden Project - Finally Installed

» Liteglow`s twin Laminar Jumping Jets :)

» Magic_Nozzle's Laminar Project

» My project build thread...

» My Laminar Garden Project - Finally Installed

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum