Liteglow`s laminar project

+2

Magic-nozzle

liteglow

6 posters

Page 2 of 4

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Wow, what a cool low pass filter, very professional, and super Expensive. Professional Parts are not cheap but very cool to use. Cant wait to see how the stream looks now. Good luck

Mario

Mario

Magic-nozzle- Nozzle Grand Master

- Posts : 287

Join date : 2009-04-02

Age : 56

Location : Europe

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

John wrote:SNOW!!! ARGH! SNOW IS GETTING IN THE WAY HERE TOO! Why won't it just warm up?!?!!?

It looks very very solid!!!!! I think you could shoot it with a tank and it would still be standing up! Looks good. I'm very excited to see the results.

What are you talking about, Snow outside?, i have 20 Degrees here. Sorry, but Spring is so nice.

I am actually diseased, and have not a lot of power, yes spring and sick .. ohh shitt.

Magic-nozzle- Nozzle Grand Master

- Posts : 287

Join date : 2009-04-02

Age : 56

Location : Europe

UPDATE !!

UPDATE !!

look what I did get today

I got 3 different sizes so I can test what I need

The size is: 200mm 220mm 250mm (7,8" - 8,6" - 9,8")

And the length is like 400mm ( 15" )

I hope that this maybe will help.

I think the best size to use is 8,6" !

The 250mm (9,8") is nice size, but when I need a box (under the grass) it will be so damn big, because the nozzle need to be tilted.

And tomorrow I will call the glass dude, and tell him to cut out a glass plate that is 6mm thick, and with a drilled hole that is 12mm in diameter (0,4") <- that will be my water output size..

Any suggestions here ?

I got 3 different sizes so I can test what I need

The size is: 200mm 220mm 250mm (7,8" - 8,6" - 9,8")

And the length is like 400mm ( 15" )

I hope that this maybe will help.

I think the best size to use is 8,6" !

The 250mm (9,8") is nice size, but when I need a box (under the grass) it will be so damn big, because the nozzle need to be tilted.

And tomorrow I will call the glass dude, and tell him to cut out a glass plate that is 6mm thick, and with a drilled hole that is 12mm in diameter (0,4") <- that will be my water output size..

Any suggestions here ?

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Those should work just fine. I'll bet even the smaller size will be sufficient for the home fountains.

Bad day :-(

Bad day :-(

Ok here is an update !!

I really dont know what is wrong here..

And I dont know where to go now

I have a 8" big pipe, 500 straws, 2-3" with air on the bottom, and on the top of the straws !

And I have a 12mm glass drilled hole on the output !

But the result was terrible, terrible, yes, bad !!

Here is the pictures:

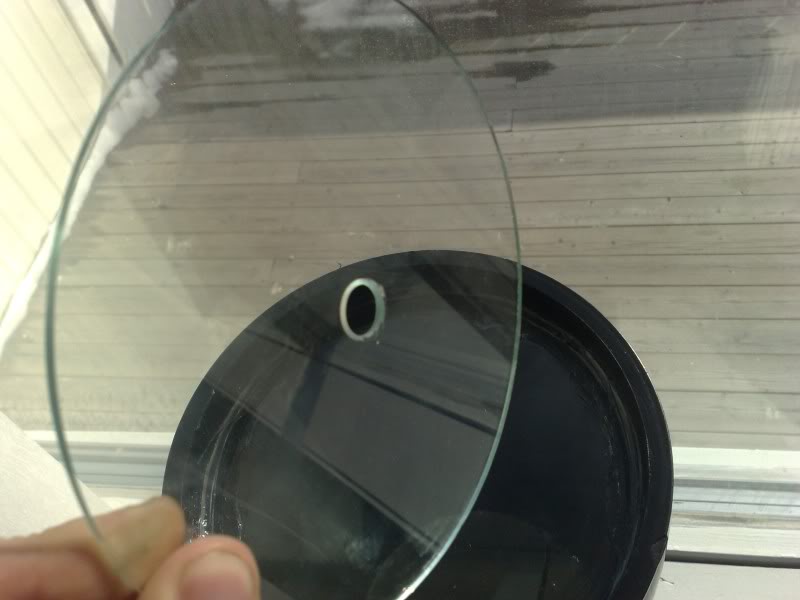

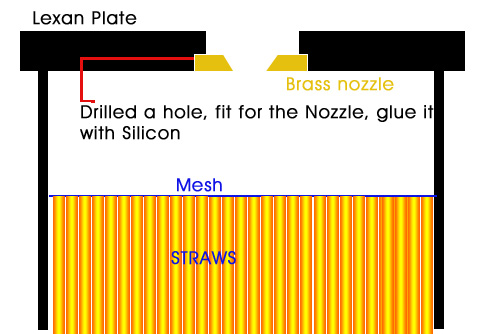

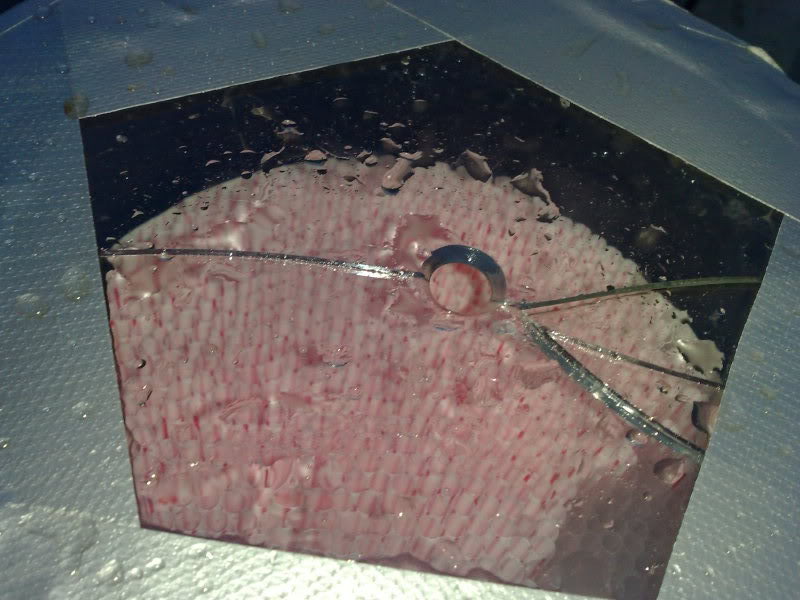

Here is the bottom, sealed with a lexan glass !

and here is the BAD output !! WHYY ?

This was not the happy ending I was hoping for.

Edit: I did one more test..

And I did study the water closer (i did even try another brass ring) !

But it seems like the water is coming up faster in the straws in the middle.. ..

Why can that happen, as the water flow in from the bottom side ..

What I will try to do is to add some filter in the bottom, maybe a sponge..

---

Edit: Now I did a test with a sponge in front of the water input (inside the nozzle) ..

And the result was allot better.. but not perfect, I think that the brass ring is the problem now..

I have fucked up the "glass" ring with some silicone and stuff.. so the water flow was like a square in this test ..

I really dont know what is wrong here..

And I dont know where to go now

I have a 8" big pipe, 500 straws, 2-3" with air on the bottom, and on the top of the straws !

And I have a 12mm glass drilled hole on the output !

But the result was terrible, terrible, yes, bad !!

Here is the pictures:

Here is the bottom, sealed with a lexan glass !

and here is the BAD output !! WHYY ?

This was not the happy ending I was hoping for.

Edit: I did one more test..

And I did study the water closer (i did even try another brass ring) !

But it seems like the water is coming up faster in the straws in the middle.. ..

Why can that happen, as the water flow in from the bottom side ..

What I will try to do is to add some filter in the bottom, maybe a sponge..

---

Edit: Now I did a test with a sponge in front of the water input (inside the nozzle) ..

And the result was allot better.. but not perfect, I think that the brass ring is the problem now..

I have fucked up the "glass" ring with some silicone and stuff.. so the water flow was like a square in this test ..

Last edited by liteglow on Mon Apr 20, 2009 12:01 pm; edited 1 time in total

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

hmmmm.....

Don't worry we'll get this working.

From the pictures it looks like you don't have a filter material.

I'm guessing here, but what is your construction layers?

It looks like you have

2" of empty space

7" of straws

2" of empty space,

Is that right?

How are the layers held in place? How are you holding the top plate in place? Does it rest up against an internal ring?

Don't worry we'll get this working.

From the pictures it looks like you don't have a filter material.

I'm guessing here, but what is your construction layers?

It looks like you have

2" of empty space

7" of straws

2" of empty space,

Is that right?

How are the layers held in place? How are you holding the top plate in place? Does it rest up against an internal ring?

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Heh.. thanx for that John .. ¤puh¤

Yes you are correct..

I have 2" free Air , straws, and then 2" free air from the output !

The straws is taped in with duck tape before I stick them inside my nozzle.

So the "pressure" is holding them tight on place...

The top and bottom is glued with silicone..

Yes you are correct..

I have 2" free Air , straws, and then 2" free air from the output !

The straws is taped in with duck tape before I stick them inside my nozzle.

So the "pressure" is holding them tight on place...

The top and bottom is glued with silicone..

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

1. How long are the straws?

2. When you are shooting the water is it ever laminar (i.e. when it is a low flow rate)?

2a. Do you know the flow rate (approximately)? It's ok if you don't.

3. Does the glass plate have a wide opening on the side touching the air?

4. Are you hooked up to a pump? Are you using the filter?

5. How far does it shoot before it become turbulent?

2. When you are shooting the water is it ever laminar (i.e. when it is a low flow rate)?

2a. Do you know the flow rate (approximately)? It's ok if you don't.

3. Does the glass plate have a wide opening on the side touching the air?

4. Are you hooked up to a pump? Are you using the filter?

5. How far does it shoot before it become turbulent?

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

John wrote:1. How long are the straws?

2. When you are shooting the water is it ever laminar (i.e. when it is a low flow rate)?

2a. Do you know the flow rate (approximately)? It's ok if you don't.

3. Does the glass plate have a wide opening on the side touching the air?

4. Are you hooked up to a pump? Are you using the filter?

5. How far does it shoot before it become turbulent?

1. I think they are 23cm = 9"

2. I did not try "low" flow.. I had the same pressure (cannot adjust) but it seems like a regular water from a tap.

2a. Dont know ...

3. The glass plate is a drilled 12mm hole, then it`s drilled with a con in both ends, so the touch plate for the water is minimum.

4. Yes I have a professional pond pump, and I have my low-pass filter connected

5. In my eyes, it seems like it never is laminar...

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

But John, remember what I did say in the other post !

When I did se inside the nozzle (first time) it seems like the water was jumping out in the straws in the middle first.

And I would guess that indicate that the water flow find the fastest way there from the water input in the nozzle.

I did try this:

Not easy to see, but I did put a sponge in front of the hosing..

What happen now is that the water goes inside the sponge, and circulate around before it slowly enter EVERY straws..

And come up slowly into the output

It seems to work better, but I still need to have a better brass ring... (magic did you hear that? )

)

When I did se inside the nozzle (first time) it seems like the water was jumping out in the straws in the middle first.

And I would guess that indicate that the water flow find the fastest way there from the water input in the nozzle.

I did try this:

Not easy to see, but I did put a sponge in front of the hosing..

What happen now is that the water goes inside the sponge, and circulate around before it slowly enter EVERY straws..

And come up slowly into the output

It seems to work better, but I still need to have a better brass ring... (magic did you hear that?

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Yeah, I think it's probably the filter layer. At first I didn't think that the filter layer was so critical, but perhaps it is.

I tried posting a file on the forum, but I couldn't get it to work, so I posted it on my blog. Something you said had me a bit confused so I wanted to make sure that we understand the top plate correctly.

check my blog for the picture. It's only going to be up there for the time being, until I figure out how to put it on the forum. www.mad-laboratory.com

I just wanted to make sure that the top plate only have a convex shape on the side that is open to the air. The other side (to the water) is completely flat. Is that how you have it?

I tried posting a file on the forum, but I couldn't get it to work, so I posted it on my blog. Something you said had me a bit confused so I wanted to make sure that we understand the top plate correctly.

check my blog for the picture. It's only going to be up there for the time being, until I figure out how to put it on the forum. www.mad-laboratory.com

I just wanted to make sure that the top plate only have a convex shape on the side that is open to the air. The other side (to the water) is completely flat. Is that how you have it?

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

No...

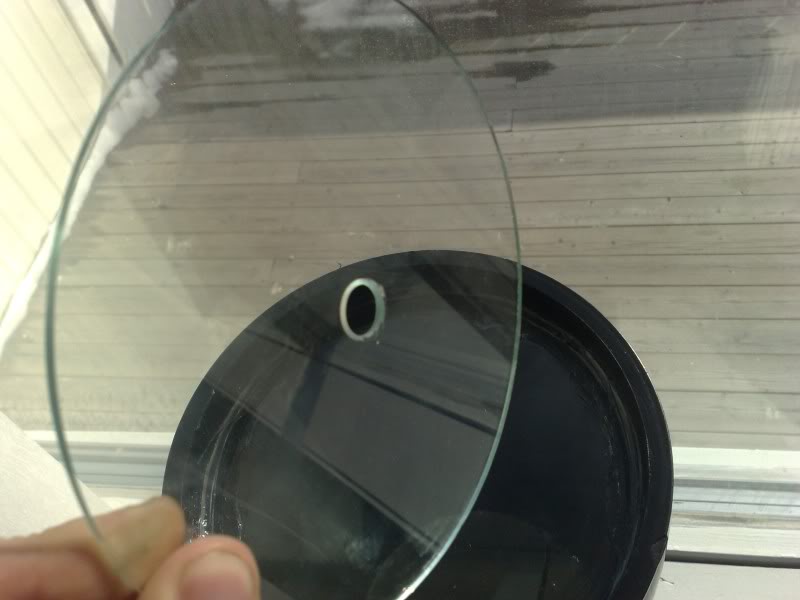

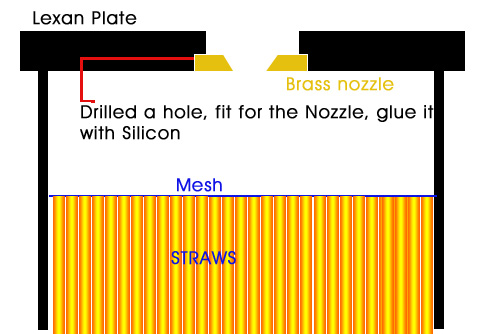

First I have a lexan (polyurthane) top plate that cover everything..

Then I did drill a HUGE hole in that top plate, so I can mount the thinner glass plate (with the output hole) over it.

I did make a picture in flash so you can se it more easy ...

on the image it`s seems like you have Cut the nozzle in half !

Do you see now how the glass is drilled ? its like a V drill, from both sides..

But there is also a distance from the BIG hole i drilled, and into the glass on top..

ask if you dont understand .

First I have a lexan (polyurthane) top plate that cover everything..

Then I did drill a HUGE hole in that top plate, so I can mount the thinner glass plate (with the output hole) over it.

I did make a picture in flash so you can se it more easy ...

on the image it`s seems like you have Cut the nozzle in half !

Do you see now how the glass is drilled ? its like a V drill, from both sides..

But there is also a distance from the BIG hole i drilled, and into the glass on top..

ask if you dont understand .

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

IMO,

That is where things are going wrong.

1. You want to have the water come up to the top and meet an abrupt end, completely flush. If you are planning on making things in multiple parts then all the parts have to be completely flush (just on the water side).

2. The nozzle piece should be "cut in half" as you were saying it. It's really hard to explain without pictures, but you want the water to hit the flat edge of the nozzle, then exit out the V. The way you have it, I'd describe yours as a double V. I'll make a short video tonight and try and describe it to you.

What is happening with your water is that it is getting accelerated through the nozzle as it approaches the exit, which makes the water turbulent again. Your nozzle is ruining all the work previous. I'll bet that is what is wrong with your system.

That is where things are going wrong.

1. You want to have the water come up to the top and meet an abrupt end, completely flush. If you are planning on making things in multiple parts then all the parts have to be completely flush (just on the water side).

2. The nozzle piece should be "cut in half" as you were saying it. It's really hard to explain without pictures, but you want the water to hit the flat edge of the nozzle, then exit out the V. The way you have it, I'd describe yours as a double V. I'll make a short video tonight and try and describe it to you.

What is happening with your water is that it is getting accelerated through the nozzle as it approaches the exit, which makes the water turbulent again. Your nozzle is ruining all the work previous. I'll bet that is what is wrong with your system.

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Thank you John

I totally understand what you are talking about !

I did never think about that when I created my top plate...

But now when you say it, it make allot more sense to me.

I did only think that the most important was the water to exit on a sharp edge..

And I did not take care that everything under was in line as you say .

So what I need to do is get a new glass plate maybe, that is the TOTAL size of my nozzle.

And in that plate there should be only ONE hole that is cutted in a V <-- that way up and down

Thanx again for your input John !!

I totally understand what you are talking about !

I did never think about that when I created my top plate...

But now when you say it, it make allot more sense to me.

I did only think that the most important was the water to exit on a sharp edge..

And I did not take care that everything under was in line as you say .

So what I need to do is get a new glass plate maybe, that is the TOTAL size of my nozzle.

And in that plate there should be only ONE hole that is cutted in a V <-- that way up and down

Thanx again for your input John !!

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Just one V, up not down! That is very important. You must understand this before you continue on.

Since I can't figure out how to post a picture. Filip. I just sent you, an edited picture of the one that you posted. Please post it for me.

Since I can't figure out how to post a picture. Filip. I just sent you, an edited picture of the one that you posted. Please post it for me.

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

I think you missunderstand .. I ment the V with the tiny opening down, and the biggest on top..

I have made a new image..

I have made a new image..

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

YES!!!! AWESOME! That's exactly how it should be. Sorry for misunderstanding....we're doing the best we can with text and images.

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

John wrote:YES!!!! AWESOME! That's exactly how it should be. Sorry for misunderstanding....we're doing the best we can with text and images.

No problem, it`s hard to explain when I dont have all the words in english that I want to say haha

Pictures is so easy ..

I use flash to create this images, quick and simple.. and very easy to understand :-)

But again, thank you for the help !!

Tomorrow there will be a new test with a completely new top plate with a V cut hole on the top !

Strange that I did never thought about that at all when I created the nozzle..

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Try take it easy Filip, no master was fallen from above. The most of us, me too, build many times things don't work. I was starting one year ago, and i am still in progress.

I am not sure your sponge is the best choice and the way you mount it in. the best is a foam, talked about this page https://laminar.forumotion.com/laminar-nozzle-talk-and-pictures-f1/magic_nozzle-s-laminar-project-t6-15.htm . But i use also a different one. Its kind a carpet, normally that is used outside in the garden. I don't know how this is called in English. but you can buy it in any big Do it your self store. A picture of the one i use.

Your nozzle size is cool, but you will need some window net (normal use is to protect from Fly's and mosquito's) to hold everything in place, specially if you plan to use it more than just one month outside.

If your nozzle is big enough, you don't need a large tangential input like John is using, but it helps a little if you like it Perfect. I don't use one.

Here is a picture how i mount my Brass nozzle in the lexan top.

can buy it in any big Do it your self store. A picture of the one i use.

I am sure, with this changes you will have a perfect stream.

To reduce the Power of your Pump!

Just make something that regulate the water input. Use scotch tape to close your pump inlet to 50% to test.

Good luck, Mario

I am not sure your sponge is the best choice and the way you mount it in. the best is a foam, talked about this page https://laminar.forumotion.com/laminar-nozzle-talk-and-pictures-f1/magic_nozzle-s-laminar-project-t6-15.htm . But i use also a different one. Its kind a carpet, normally that is used outside in the garden. I don't know how this is called in English. but you can buy it in any big Do it your self store. A picture of the one i use.

Your nozzle size is cool, but you will need some window net (normal use is to protect from Fly's and mosquito's) to hold everything in place, specially if you plan to use it more than just one month outside.

If your nozzle is big enough, you don't need a large tangential input like John is using, but it helps a little if you like it Perfect. I don't use one.

Here is a picture how i mount my Brass nozzle in the lexan top.

can buy it in any big Do it your self store. A picture of the one i use.

I am sure, with this changes you will have a perfect stream.

To reduce the Power of your Pump!

Just make something that regulate the water input. Use scotch tape to close your pump inlet to 50% to test.

Good luck, Mario

Magic-nozzle- Nozzle Grand Master

- Posts : 287

Join date : 2009-04-02

Age : 56

Location : Europe

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

I still haven't found the material that I really want to use for the filter. I have some filter material that will work for the time being, but I need to find that reticulated foam. I believe that the word that for the fish filter stuff.

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

Thank you again for the input John and Mario !!

I know about the sponge not be the best..

But I have not yet found any filter of the one you have.

I know I have a filter like that in my vacuum cleaner, but I cannot take that out

Anyway HERE IS THE PICTURE OF MY UPDATE

Check out this new cut in the glass plate

Not P E R F E C T !! but "OK"

And check out the result !!

I`m very happy with the result..

On the picture it was from the house tap, but did also try from the pump with the same result..

The beam is laminar, but the cut in the glass is not so perfect that I had hoped..

So I think I need to use a drilled brass ring for my output..

but after all, I really like the result of the tip from John about how to mount the output !!

The problem was to mount the glass on the pipe..

I did have the silicone on, and after 10 min I go outside and test haha..

But the time for silicone to get hard is 10-20 hours

So the water did leak everywhere.... but wtf the result was perfect

THANK YOU EVERYBODY

I know about the sponge not be the best..

But I have not yet found any filter of the one you have.

I know I have a filter like that in my vacuum cleaner, but I cannot take that out

Anyway HERE IS THE PICTURE OF MY UPDATE

Check out this new cut in the glass plate

Not P E R F E C T !! but "OK"

And check out the result !!

I`m very happy with the result..

On the picture it was from the house tap, but did also try from the pump with the same result..

The beam is laminar, but the cut in the glass is not so perfect that I had hoped..

So I think I need to use a drilled brass ring for my output..

but after all, I really like the result of the tip from John about how to mount the output !!

The problem was to mount the glass on the pipe..

I did have the silicone on, and after 10 min I go outside and test haha..

But the time for silicone to get hard is 10-20 hours

So the water did leak everywhere.... but wtf the result was perfect

THANK YOU EVERYBODY

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

That does look good! GOOD JOB!

What's next? Are you going to try to improve it or are you onto the lighting and cutting?

What's next? Are you going to try to improve it or are you onto the lighting and cutting?

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

John wrote:That does look good! GOOD JOB!

What's next? Are you going to try to improve it or are you onto the lighting and cutting?

This was only a test to figure out if the nozzle size was OK.. and it is !

But the first problem is how to seal the Top and bottom !!

As I cannot glue it with silicone (the silicone don't stick to this plastic material) .

But that is a easy to fix problem, I can just use some long screws, or make something else smart

But yes light is something I will test out. (but not so sure if I bother to work on the lights now..

Because it will not be dark outside until august-September... (4-5 months with sun all day and night

So yes when I find the solution how to make the top\bottom to be water tight..

I will start working on the cutter .

I`m starting to dig in the garden next week, so I had a plan to maybe have all 4 nozzles completed before Mai is over.

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

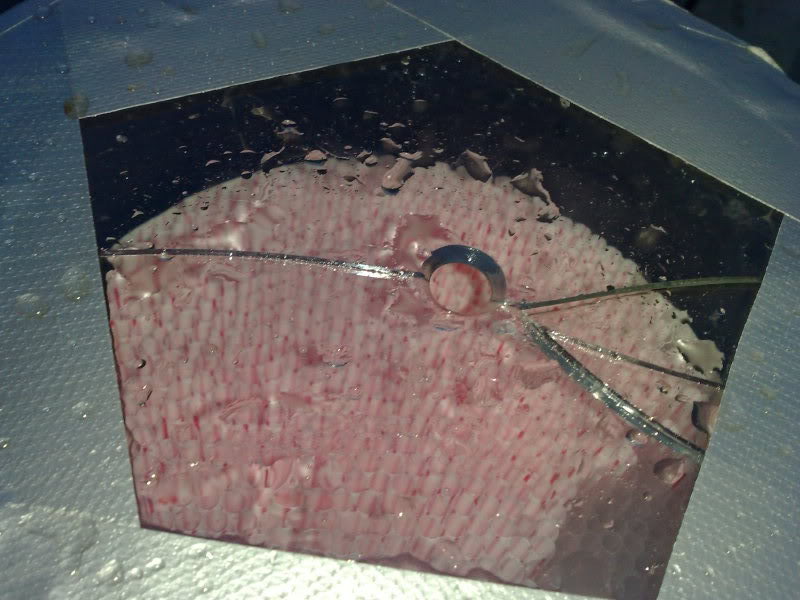

Did one more try today...

But I was not able to seal the glass with silicone, so I did use allot of duck tape

Anyway, it seems like there is more pressure inside this nozzle that I was aware of ..

Just look at the picture:

So it`s over for the glass !

But it does not matter, I will not use glass anyway, because of the bad edge on the cut .

But I was not able to seal the glass with silicone, so I did use allot of duck tape

Anyway, it seems like there is more pressure inside this nozzle that I was aware of ..

Just look at the picture:

So it`s over for the glass !

But it does not matter, I will not use glass anyway, because of the bad edge on the cut .

Re: Liteglow`s laminar project

Re: Liteglow`s laminar project

That's too bad for the glass! I thought it was a pretty creative solution.

( I give it a 4 out of 5 light bulb idea, it would have been 5 if it would have worked) It also seemed like it was quick turn around time. There should be a way to completely seal it because that's what aquariums use. ....Well I guess they probably have all glass touching glass huh.

( I give it a 4 out of 5 light bulb idea, it would have been 5 if it would have worked) It also seemed like it was quick turn around time. There should be a way to completely seal it because that's what aquariums use. ....Well I guess they probably have all glass touching glass huh.

I have some extra brass rings that I could sell you.

I have some extra brass rings that I could sell you.

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» Magic_Nozzle's Laminar Project

» Mr Webb's Laminar Project.

» Jetty's Wifi Web Based Laminar Jet Project

» Ike's Prototype Project - My first laminar nozzle

» My Laminar Garden Project - Finally Installed

» Mr Webb's Laminar Project.

» Jetty's Wifi Web Based Laminar Jet Project

» Ike's Prototype Project - My first laminar nozzle

» My Laminar Garden Project - Finally Installed

Page 2 of 4

Permissions in this forum:

You cannot reply to topics in this forum