Making a laminar flow 2 m high and 4 m far

2 posters

Page 1 of 1

Making a laminar flow 2 m high and 4 m far

Making a laminar flow 2 m high and 4 m far

Hello everyone.

I am Peter from Belgium.

I'd like to make a laminar flow fountain because my lovely wife saw one and she absolutely loved it.

Actually, I wanted to make three of them and place them in a cascade – to have a little more of a challenge.

While I was searching the internet, I came across this site where I found the necessary information and ideas.

Thanks to you all for that.

So, I started building one, testing and playing a little, trying to make it work.

First I made an excel-file to calculate the fountain.

You just have to enter the wanted height and range of the water jet together with the diameter of the nozzle.

Excel will calculate the angle in which you have to place the fountain – necessary pressure of the pump (not taking the pipe resistance in account)

By putting different values of the diameter of the straws and the tube, Excel will calculate also the Reynolds number.

This number should stay under 2300.

That's the first time I could use the theory I learned at school in practice.

The composition is looking like this:

• A PVC tube with a diameter of 160 mm , length 300 mm.

• The bottom has a cap you can take on and off, glued to the PVC tube .

• The upper side of the PTFE (teflon) disc with a hole in the middle – perfectly flat.

In this hole there is a braze nozzle, conical 9 mm.

• In the tube there are straws, diameter 8 mm – length 220 mm

The straws are kept in place by 2 window screen pieces.

• Waterinlet is a 1” nippel – mounted at de bottom of the PVC tube with a curve 90° inside – the bigger the inlet and water pipe the lower the flow

resistance – the further and higher the water jet.

There are no sponges used – I noticed no difference if the sponges were places or not – and again, the less resistance, the further and higher the water

jet – instead I used an extra window screen piece.

https://i.servimg.com/u/f97/19/54/21/55/img_3318.jpg

https://i.servimg.com/u/f97/19/54/21/55/img_3320.jpg

• Pump info : 5 m³/h – 0,5 bar

• Low pass filter, height 1 m – diameter 160 mm

Assembly dimensions :

• 3 cm of free space

• 1 extra window screen piece

• 2 cm free space

• 1 window screen piece

• 220 mm straws

• 1 window screen piece

• 3 cm free space

• teflon disc with brass nozzle 9 mm indiameter

Assembly LED lightning :

• 1 RGB LED 3 Watt build in a waterproof box.

• 1 PMMA round rod 10 mm – placed in the middle of the tube - end of the rod 2 cm from the teflon disc – nearer to the teflon disc causes turbulence of

the water jet.

I tried fiberglass with little success.

• A Arduino Uno with a RGB driver to control the RGB LED – with a little program to make color effects.

Assembly of the cutter :

• 1 stepper motor Nema 17 build in a waterproof box.

• A Arduino with a stepper motor driver TB6560 3A to control the motor – with an little program to create a play of the cutter.

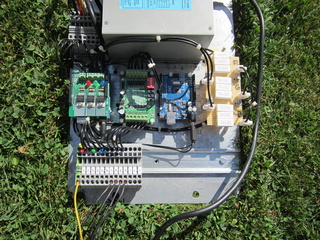

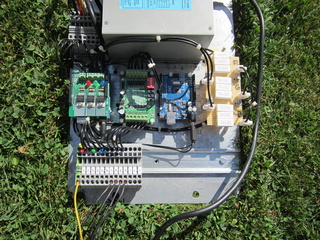

Together with an old PC power supply you get something like this :

- left : RGB driver with arduino underneath

- second : driver stepper motor

- third : arduino for the stepper motor

- fourth : resistance for the RGB LED

It is not so bad for the first attempt.

There are still 2 problems I have :

Problem 1 : the waterjet,

The nozzle is able to produce a water jet of 3 m high en 6 m far – unfortunately with a brake up of the water jet 1 meter after the top of the water jet.

I just want a water jet of 2 m high en 4 m far. But there is also a break up after about 0,75 m after the top of the jet.

I tried everything – new brass nozzles – sanded – extra sanded – smaller outlet diameter – bigger outlet diameter – with and without low pass filter – small or big air bubble in the low pass filter.

Nothing seems to help. Reynolds number is never a problem.

The water jet is very stable.

What else can I try ?

Problem 2 : the cutter.

The cutter is very fast.

Stopping the water jet seems ok.

But when the cutter gets open again, there are a lot of water drops at the beginning of the water jet – not acceptable.

I am sure the reason is situated in the disturbance of the water jet underneath the cutter when the cutter is active.

In this case the cutter is simply a metal strip. I think it should be a special shape.

Is there anyone who has some experience ?

Who can give me some advice ?

Thanks.

I am Peter from Belgium.

I'd like to make a laminar flow fountain because my lovely wife saw one and she absolutely loved it.

Actually, I wanted to make three of them and place them in a cascade – to have a little more of a challenge.

While I was searching the internet, I came across this site where I found the necessary information and ideas.

Thanks to you all for that.

So, I started building one, testing and playing a little, trying to make it work.

First I made an excel-file to calculate the fountain.

You just have to enter the wanted height and range of the water jet together with the diameter of the nozzle.

Excel will calculate the angle in which you have to place the fountain – necessary pressure of the pump (not taking the pipe resistance in account)

By putting different values of the diameter of the straws and the tube, Excel will calculate also the Reynolds number.

This number should stay under 2300.

That's the first time I could use the theory I learned at school in practice.

The composition is looking like this:

• A PVC tube with a diameter of 160 mm , length 300 mm.

• The bottom has a cap you can take on and off, glued to the PVC tube .

• The upper side of the PTFE (teflon) disc with a hole in the middle – perfectly flat.

In this hole there is a braze nozzle, conical 9 mm.

• In the tube there are straws, diameter 8 mm – length 220 mm

The straws are kept in place by 2 window screen pieces.

• Waterinlet is a 1” nippel – mounted at de bottom of the PVC tube with a curve 90° inside – the bigger the inlet and water pipe the lower the flow

resistance – the further and higher the water jet.

There are no sponges used – I noticed no difference if the sponges were places or not – and again, the less resistance, the further and higher the water

jet – instead I used an extra window screen piece.

https://i.servimg.com/u/f97/19/54/21/55/img_3318.jpg

https://i.servimg.com/u/f97/19/54/21/55/img_3320.jpg

• Pump info : 5 m³/h – 0,5 bar

• Low pass filter, height 1 m – diameter 160 mm

Assembly dimensions :

• 3 cm of free space

• 1 extra window screen piece

• 2 cm free space

• 1 window screen piece

• 220 mm straws

• 1 window screen piece

• 3 cm free space

• teflon disc with brass nozzle 9 mm indiameter

Assembly LED lightning :

• 1 RGB LED 3 Watt build in a waterproof box.

• 1 PMMA round rod 10 mm – placed in the middle of the tube - end of the rod 2 cm from the teflon disc – nearer to the teflon disc causes turbulence of

the water jet.

I tried fiberglass with little success.

• A Arduino Uno with a RGB driver to control the RGB LED – with a little program to make color effects.

Assembly of the cutter :

• 1 stepper motor Nema 17 build in a waterproof box.

• A Arduino with a stepper motor driver TB6560 3A to control the motor – with an little program to create a play of the cutter.

Together with an old PC power supply you get something like this :

- left : RGB driver with arduino underneath

- second : driver stepper motor

- third : arduino for the stepper motor

- fourth : resistance for the RGB LED

It is not so bad for the first attempt.

There are still 2 problems I have :

Problem 1 : the waterjet,

The nozzle is able to produce a water jet of 3 m high en 6 m far – unfortunately with a brake up of the water jet 1 meter after the top of the water jet.

I just want a water jet of 2 m high en 4 m far. But there is also a break up after about 0,75 m after the top of the jet.

I tried everything – new brass nozzles – sanded – extra sanded – smaller outlet diameter – bigger outlet diameter – with and without low pass filter – small or big air bubble in the low pass filter.

Nothing seems to help. Reynolds number is never a problem.

The water jet is very stable.

What else can I try ?

Problem 2 : the cutter.

The cutter is very fast.

Stopping the water jet seems ok.

But when the cutter gets open again, there are a lot of water drops at the beginning of the water jet – not acceptable.

I am sure the reason is situated in the disturbance of the water jet underneath the cutter when the cutter is active.

In this case the cutter is simply a metal strip. I think it should be a special shape.

Is there anyone who has some experience ?

Who can give me some advice ?

Thanks.

peter.lefevre2@telenet.be- Nozzle Newbie

- Posts : 2

Join date : 2016-09-10

Age : 57

Location : Belgium

Re: Making a laminar flow 2 m high and 4 m far

Re: Making a laminar flow 2 m high and 4 m far

Hello Peter!

Thanks for sharing your wonderful build! Everything looks great and well built!

In regards to your two problems, here are my suggestions:

Problem 1) It sounds like you have great results so far, and you have taken many of the steps needed to prevent breakup of the water. It would probably be helpful to look at the breakup area and try to understand "how" the water is breaking up. If it were pressure fluctuations, you would probably see the solid part of the stream move back and forth as the pressure fluctuated. Another possibility is wind! I have found that on a long stream, even a gentle breeze can cause problems. Perhaps you have a place indoors to try your stream where you can take all of the wind out of the equation? The third possibility is the diameter of your nozzle. While your Reynolds number is perfectly fine, I have had more success by using a wider diameter pipe. My current nozzle is 8 inches (20cm) wide. Hopefully one of these ideas help, they are all I can think of right now.

Problem 2) With the cutter, mechanical moving parts never seem to be fast enough to cut the water well. Whenever I see a jumping fountain that has been professionally installed, I always go over and see how it is working, and they always are using a separate water stream to "cut" the water. In case you are not familiar, I will explain in detail.

You have the output of your laminar jet, and it goes out of the nozzle and then through a second opening. This second opening has plenty of clearance for the stream of water. Let's say it is 2-3 times as wide as your stream of water. The laminar stream is always flowing. A second, non-laminar stream of water, typically something that comes from a smaller nozzle (something like holding your thumb over a garden hose) is shot at the laminar stream, which pushes it off to the side and it does not come out of that second opening. When you turn off this second stream of water (I'll call it the diverting stream), the laminar stream will flow out like normal. When you turn it on, it cuts the water.

Hope that helps, would love to hear back on your progress! Best of luck!

Thanks for sharing your wonderful build! Everything looks great and well built!

In regards to your two problems, here are my suggestions:

Problem 1) It sounds like you have great results so far, and you have taken many of the steps needed to prevent breakup of the water. It would probably be helpful to look at the breakup area and try to understand "how" the water is breaking up. If it were pressure fluctuations, you would probably see the solid part of the stream move back and forth as the pressure fluctuated. Another possibility is wind! I have found that on a long stream, even a gentle breeze can cause problems. Perhaps you have a place indoors to try your stream where you can take all of the wind out of the equation? The third possibility is the diameter of your nozzle. While your Reynolds number is perfectly fine, I have had more success by using a wider diameter pipe. My current nozzle is 8 inches (20cm) wide. Hopefully one of these ideas help, they are all I can think of right now.

Problem 2) With the cutter, mechanical moving parts never seem to be fast enough to cut the water well. Whenever I see a jumping fountain that has been professionally installed, I always go over and see how it is working, and they always are using a separate water stream to "cut" the water. In case you are not familiar, I will explain in detail.

You have the output of your laminar jet, and it goes out of the nozzle and then through a second opening. This second opening has plenty of clearance for the stream of water. Let's say it is 2-3 times as wide as your stream of water. The laminar stream is always flowing. A second, non-laminar stream of water, typically something that comes from a smaller nozzle (something like holding your thumb over a garden hose) is shot at the laminar stream, which pushes it off to the side and it does not come out of that second opening. When you turn off this second stream of water (I'll call it the diverting stream), the laminar stream will flow out like normal. When you turn it on, it cuts the water.

Hope that helps, would love to hear back on your progress! Best of luck!

theguitarman- Nozzle Newbie

- Posts : 24

Join date : 2011-02-16

Re: Making a laminar flow 2 m high and 4 m far

Re: Making a laminar flow 2 m high and 4 m far

Hi theguitarman,

thanks for the suggestions.

I made already 2 holes, distance between the holes amounts 4 meters.

1 hole for the pump, the other one for de nozzle.

Tried it and it wasn't bad.

4 meters is the max distance with almost no breakup of the beam.

Reynolds number is 438. ( nozzle = 160 mm ).

Reynols number with a 200 mm nozzle will be 280.

This summer, I'll finish the project - just 1 beam in stead of 3 beams ( my first intention ).

I struggle a bit with the light - the beam isn't bright enough.

There is not enough power.

Working with an optic tube with a power RGB LED ( 10 Watt ) want do the job.

Somehow i need a brighter light without using a optic tube.

I"ll keep you inform.

Grests , Peter

thanks for the suggestions.

I made already 2 holes, distance between the holes amounts 4 meters.

1 hole for the pump, the other one for de nozzle.

Tried it and it wasn't bad.

4 meters is the max distance with almost no breakup of the beam.

Reynolds number is 438. ( nozzle = 160 mm ).

Reynols number with a 200 mm nozzle will be 280.

This summer, I'll finish the project - just 1 beam in stead of 3 beams ( my first intention ).

I struggle a bit with the light - the beam isn't bright enough.

There is not enough power.

Working with an optic tube with a power RGB LED ( 10 Watt ) want do the job.

Somehow i need a brighter light without using a optic tube.

I"ll keep you inform.

Grests , Peter

peter.lefevre2@telenet.be- Nozzle Newbie

- Posts : 2

Join date : 2016-09-10

Age : 57

Location : Belgium

Similar topics

Similar topics» Output side of laminar nozzle

» What can cause the laminar flow to break?

» The guide to laminar flow..

» My first try at a laminar flow nozzle

» For what reason can the laminar flow be dispersed?

» What can cause the laminar flow to break?

» The guide to laminar flow..

» My first try at a laminar flow nozzle

» For what reason can the laminar flow be dispersed?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|